Industrial robotics refers to the use of robots in manufacturing and other industrial applications. These robots are designed to perform repetitive tasks with a high degree of accuracy and speed. They can be programmed to perform a wide range of functions, including assembly, welding, painting, packaging, material handling, and more. Industrial robots are typically highly specialized machines that are designed for specific industrial processes.

They are often used in environments that are hazardous or inaccessible to humans, and can work 24/7 without getting tired, increasing productivity and efficiency in many industries. The integration of advanced technologies such as artificial intelligence, machine learning, and computer vision has further expanded the capabilities of industrial robots and their use in various applications.

Industrial robots perform a wide range of tasks in manufacturing and other industrial applications. Some common tasks that industrial robots perform include:

- Assembly: Robots can be programmed to assemble products by assembling various parts and components.

- Welding: Robots can be equipped with welding equipment to weld parts together, resulting in a stronger bond.

- Painting: Robots can be programmed to paint objects, such as car bodies, with high accuracy and speed.

- Packaging: Robots can be used to package products, such as food and consumer goods, in a consistent and efficient manner.

- Material handling: Robots can be used to move heavy loads, such as raw materials and finished products, around a manufacturing facility.

- Quality control: Robots can be equipped with cameras and other sensors to perform quality control checks on products.

- Machine tending: Robots can be used to load and unload materials from machines, such as CNC machines and presses.

Overall, industrial robots are designed to perform repetitive tasks that are dangerous, repetitive, or difficult for humans to perform, increasing efficiency and productivity in the process.

Can we make Industrial Robotics?

Yes, you can make industrial robots, although it is a complex and specialized process that typically requires a high level of technical expertise and resources. Building industrial robots typically involves designing and engineering the mechanical and electrical components, programming the software and control systems, and integrating various sensors, actuators, and other components to create a functional machine.

If you have the technical expertise and resources, you can start by researching the different types of industrial robots, the applications they are commonly used for, and the components and technologies that are required to build them. You may also need to work with specialists in fields such as mechanical engineering, electrical engineering, computer science, and control systems to ensure that the robot is designed and built to meet the desired specifications.

It’s important to note that building industrial robots is not a simple or inexpensive process, and requires significant investment in time, resources, and expertise. If you do not have the necessary technical skills and resources, it may be more practical to purchase an industrial robot from a reputable manufacturer or supplier.

What types of electronic comonents need for make?

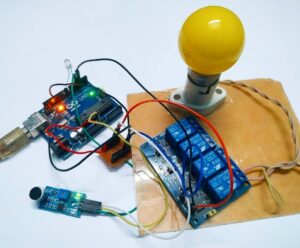

To build an industrial robot, you will need a variety of electronic components, including:

- Microcontrollers: These are the brains of the robot, responsible for processing the inputs from sensors, controlling the actuators, and running the robot’s software.

- Motors: Motors are used to control the movement of the robot’s joints and limbs. There are several types of motors that can be used, including DC motors, stepper motors, and servo motors.

- Actuators: Actuators are devices that convert the electrical energy from the motors into mechanical energy to power the movement of the robot.

- Sensors: Sensors are used to gather information about the environment and the robot’s surroundings, including information about position, orientation, and the presence of objects. Common sensors used in industrial robots include encoders, position sensors, proximity sensors, and vision sensors.

- Power supplies: Industrial robots typically require a high level of power to operate, so you will need a robust power supply system to provide the necessary energy.

- Cabling and wiring: To connect the various components of the robot, you will need a variety of cabling and wiring, including power cables, data cables, and control cables.

- Control systems: The control system is responsible for controlling the robot’s movements and ensuring that it performs the desired actions. The control system typically includes software, electronics, and other components to manage the robot’s movements.

These are just a few of the key components that you will need to build an industrial robot. Depending on the specific requirements of your robot, you may also need additional components, such as servo controllers, amplifiers, and other specialized components.

Components where to buy at best price in India?

There are several places in India where you can purchase the electronic components you need to build an industrial robot at competitive prices. Some of the most popular options include:

- Online marketplaces: There are several online marketplaces in India, such as Zbotic.in where you can purchase a wide range of electronic components at competitive prices.

When purchasing components, it’s important to consider factors such as price, quality, and delivery time, and to compare prices across different suppliers to ensure that you get the best possible deal. Additionally, it’s a good idea to check the reviews and ratings of the supplier before making a purchase to ensure that you are buying from a reputable source.

Industrial Robot how they help?

Industrial robots can help in a variety of ways, including:

- Increased efficiency: Industrial robots are designed to perform tasks quickly, accurately, and consistently, leading to increased efficiency and productivity in the manufacturing process.

- Improved quality: Robots can be programmed to perform quality control checks on products, ensuring that products are consistent and of high quality.

- Cost savings: Industrial robots can help reduce labor costs by performing tasks that would otherwise be performed by humans, and they can also help reduce production downtime by working around the clock without the need for breaks or vacation time.

- Improved safety: By performing tasks that are dangerous, repetitive, or difficult for humans to perform, industrial robots can help reduce the risk of injury and increase the overall safety of the workplace.

- Increased versatility: Industrial robots can be programmed to perform a wide range of tasks, making them highly versatile and able to adapt to changing manufacturing requirements.

- Better working conditions: By performing tasks that are physically demanding, repetitive, or unpleasant, industrial robots can help improve the working conditions for human employees, who can then focus on higher-level tasks that are more engaging and rewarding.

- More sustainable manufacturing: Industrial robots can help reduce waste and improve resource efficiency, making the manufacturing process more sustainable and environmentally friendly.

Overall, industrial robots can help companies to increase efficiency, improve quality, reduce costs, enhance safety, and create a more sustainable and productive manufacturing environment.

Conclusion

In conclusion, industrial robots play a crucial role in modern manufacturing, helping to increase efficiency, improve quality, reduce costs, enhance safety, and create a more sustainable and productive manufacturing environment. With their ability to perform tasks quickly, accurately, and consistently, industrial robots are transforming the manufacturing landscape, enabling companies to stay competitive in a rapidly changing global market.

Whether working alongside human employees or operating independently, industrial robots are essential components of many modern production facilities, helping to drive innovation and growth in the manufacturing sector.

Leave a reply